Paper production process

Liner and fluting papers can be manufactured from primary wood fibres from sustainably managed forests and/or from recovered fibres from paper for recycling. As a general rule, kraftliner and semi chemical fluting are manufactured from predominantly primary fibres whereas testliner and recycled fluting are predominantly manufactured from recovered fibres.

Production of liner and fluting is typically performed at an integrated pulp and papermill (meaning that the pulp and the paper are produced at one single site, and the wet pulp is pumped directly to the paper machine with no additional drying or transport required).

For mills utilising primary wood fibre, most of the wood is delivered in the form of pulpwood logs. A proportion is also brought in as wood chips, a by-product of nearby sawmills. The pulpwood logs have to be debarked and chipped before pulping. For Kraftliner production, the kraft pulping process is used. This is a highly alkaline cooking process with caustic soda and sodium sulphide as active cooking chemicals. The cooking takes place in a digester at high pressure and a temperature of 150 -170 oC. The pulp yield is normally around 55% (i.e. 1000 kg of dry wood gives 550 kg of pulp).

For semi chemical fluting production, the wood chips are converted into pulp by the semi chemical cooking process. It is a slightly alkaline cooking process most commonly using sodium sulphite and sodium carbonate as active cooking chemicals. The pulp yield is normally around 80%.

The spent cooking liquor is drained off and washed out from the pulp. It contains the wood substance dissolved during the cooking together with the spent cooking chemicals. The spent liquor is concentrated and burnt as a fuel for energy production and recovery of cooking chemicals. The pulp produced is defiberized in refiners, screened and washed before being sent to the paper mill.

For mills utilising recovered fibres, the main recovered paper grade utilised for manufacture of testliner

and recycled fluting is old corrugated cases 2, meaning that most of the fibres are recycled in a closed loop system.

The bales of recovered paper are submerged in water and the mixture is agitated so that the paper is broken up to form a pumpable suspension. Large non-paper components such as pieces of plastics, wood, metal and textiles are removed using a “ragger” or “junker” and smaller remaining non-paper components are removed by screening and cleaning. The hot pulp may also undergo a disperging treatment, in which contaminants such as hot melt, wax, ink and coating binders loosen from the fibres and together with small fragments of paper are reduced to fine particles which are no longer visible. Pulp for recycled fibre-based paper for corrugated packaging does not normally undergo a deinking process.

For pulps from both primary fibres and recycled fibres, functional chemicals, fillers and other pulps can be added to give the final paper the properties required.

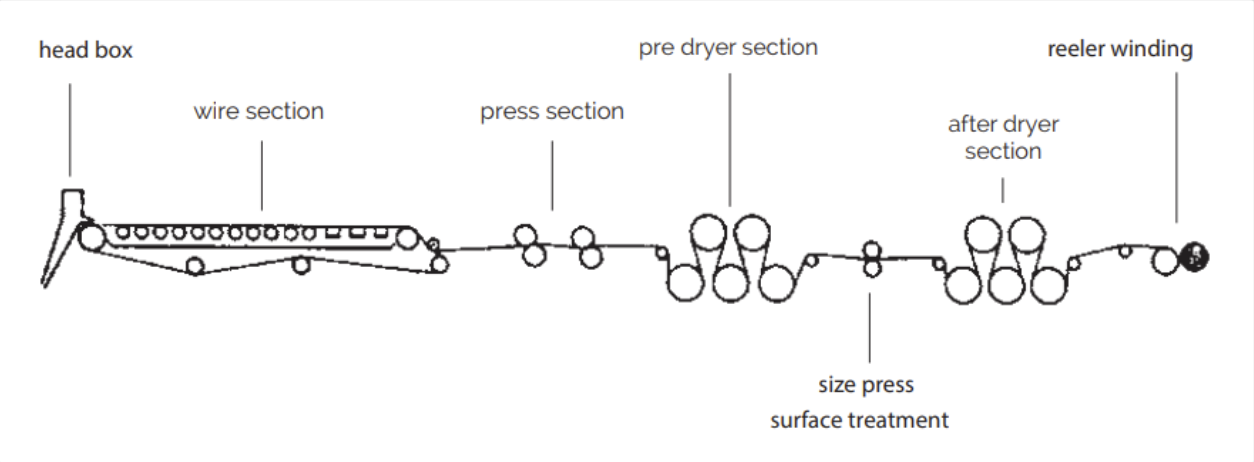

Figure 3 shows an example of the production stages for a typical paper machine. The wet stock passes through one or two headboxes onto the paper machine. The paper web is formed from the head box onto the wire and dewatered primarily by the action of gravity and vacuum. Further dewatering by mechanical means takes place in the press section where water is taken out of the sheet by pressing between felts. The final drying takes place in the drying section of the paper machine where the sheet runs against steam heated cylinders to get its final dryness of 91-93%. The collected water is reused for diluting the thick stock coming from the stock preparation.

Fig. 1: Example of paper machine for containerboard grades

Semi chemical fluting is a paper with just one ply and therefore the paper machine has one headbox and one wire. Kraftliner is normally a two-ply product and therefore requires a paper machine with two headboxes and usually two wires. The base brown ply contains the internal machine broke pulp in addition to wood fibres from the usually integrated pulp production and could also contain recycled paper pulp. The top ply is normally wood pulp from the integrated pulp production that is more refined and cleaner to give the top surface the right characteristics and printability. For white surface grades bleached fibres are used for the top ply.

Testliner mostly consists of two plies of paper. Different mixes of recovered pulp stock will be used in each layer. Generally, a better grade of mix is used for the upper layer for reasons of appearance and strength.

In order to increase its strength testliner receives a surface treatment in the size press. This involves the application of a starch solution to one or both sides of the sheet. The top ply of testliner is given an even, mostly brown colour by colouring the mass or by means of the size press treatment. This colouring is never given to white top testliners. The addition of special additives (in the mass or by means of the size press) makes it possible to produce testliners with special properties, including extra water-repellent, low-germ and anti-corrosion grades.

Recycled fluting can be a one-ply or two-ply product. Usually, a size press treatment with a starch solution is applied in-line on the paper machine in order to obtain sufficient strength and stiffness properties

After the paper machine there is a slitter winder where the jumbo reel from the paper machine is rewound and cut down to customer reel formats according to customer orders. These reels are weighed, marked, labelled and prepared for shipment to the customer, the corrugated board industry.

Corrugated base papers comprise the largest share of paper and board production in Europe, representing 37% of total paper and board production. European production of corrugated base papers in 2020 stood at 30.1 million tonnes3. The majority of product is produced from recovered fibres. 88% of corrugated packaging is derived from recycled content. Corrugated base papers have a paper for recycling utilisation rate of 94% and use 61% of total paper for recycling volumes used by the industry 4.

Table 1 summarises the base paper consumption for corrugated board in 2020.

| Fibre composition | |||

|---|---|---|---|

| Million tonnes | Total | Primary | Recycled |

| Kraftliner | 4.4 | 3.2 | 1.2 |

| Testliner | 12.5 | 12.5 | |

| Other recycled liner (Schrenz) | 1.0 | 1.0 | |

| Semi chemical fluting | 0.6 | 0.5 | 0.1 |

| Recycled fluting | 11.6 | 11.6 | |

| 30.1 | 3.7 | 26.4 | |

| 12% | 88% | ||